Patents

Our goal is building with wood

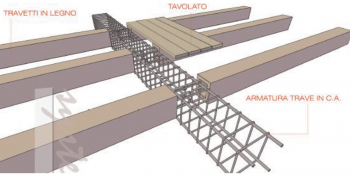

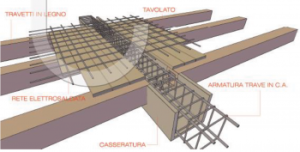

What is J-System

Advantages

J-System, the alternative and more effective solution ocmpared to brick-cement floors, becomes Smart by integrating sencros based on fiber optic technology into the steel bars with improved adhesion.

J-System Smart creates structures with self-diagnostic capabilities, equipped with a permanently integrated monitoring system of the structural nodes of the deck.

J-System reduces construction times and simplifies construction site management because:

1. Facilitates handling and installation of construction elements, which are far lighter and easier to handle than traditional reinforced concrete beams and pinatas;

2. Requires lower costs of shoring and temporary works during installation and casting phase of the floor;

3. Guarantees greater felxibility of the structural system through the possibility of modifying the length of the beams on site with simple tools and rapid economical processing

4. Eliminates the need to resort to specialized workers, for example for cutting wood and for design and installation of connection brackets.

J-System reduces costs because:

1. Guarantees shorter construction times, with consequent overall savings on construction site costs;

2. It allows for greater lightness of the structures, therefore by creating lighter floors that place less weight on the vertical structures, it determines an overall saving on the costs of the elevated structures and allows structures characterized by less vulnerability to horizontal actions of a seismic nature;

3. Requires fewer finishing costs since following the dismantling of the shoring, the exposed wooden floor is already finished, thus avoiding any plastering and painting necessary in traditional brick-and-cement floors

J-System increases the possibilities of choice and customization of finishes because:

1. Eliminates the presence of traditional steel plates and the inaccuracies that the use of this system entails;

2. Allows the choice between different aestethic and architectural solutions, allowing floors with wooden beams of different essences and finishes, and decks in planking tiles or other brick elements.

What is M-System

Functions

- Humidity measurements

- Thermal gradient measurements

- Wall inclination measurements

- Remote data management on Web Server

- Internal temperature measurements

- Low installation costs

- External temperature measurements

Characteristics

- Microcontroller based instrument

- SD memory card slot

- GPRS or WiFi/Ethernet modem

- Relative error in measurements <2%

- Powered by mains electricity

- Possibility to deploy up to 32 nodes

- Wired/WiFi system

J SYSTEM e M SYSTEM are both registered patents of Legnotek Srl